Importance of Recycling:

Importance of Recycling:

The remaining non-recyclable general terms of use of recycling waste materials as raw materials in a variety of recycling methods and the improvement of manufacturing processes again.

Importance of Recycling

Natural resources are protected; natural resources, the world population and consumption patterns change due to decreases with each passing day. Therefore, to reduce material consumption, waste recycling can be evaluated by means of qualified natural resources must be used efficiently.

Energy savings; recycling, saving energy by reducing the number of materials in the production of industrial action.

Contribution to the economy is provided recycling economically efficient long-term investment. Reducing the consumption of energy and natural resources is of great importance for the country's economy. In addition, we are dependent on foreign sources of raw materials such as oil economy has a positive effect on the decrease in consumption.

Reduces the amount of waste; reduction in the amount of recycling and waste going to harm to the environment is reduced.

Production Process:

Production Process:

Recycling plant, only the production of industrial discharges (PP yarn waste, non-woven fabric wastage, PP synthetic bag discharges) melted. Therefore, we will start the collection of recycling firelerinin stages of production from industrial plants;

- Defects collection,

- Separated according to color and viscosity values of the wastage from our hotel, facilities are stacked in the storage areas,

- Waste to be used in the production group, for the purpose of crushing machine breaks through the melting of the arrival of appropriate size,

- Broken wastage, dandruff has become. Eritilebilmesi bran extruder is passed for the thickening process. During this process, bran, by means of a blade rotating at a high velocity in the chamber is made an intensive friction,

Intensive bran, depending on the type of plastic extruder machine uygulunan melted due to the different temperatures of interest,

Cooled from the molten plastic extruder again, by means of rotating blades cut into granules are stored in a silo,

Stored in granules packed in order to make them suitable for sale, stacked within the facility.

In short, What is plastic?

In short, What is plastic?

Plastics are derived from petroleum or petroleum derivatives. There are different types of plastics. These species are primarily PET (Polietilentetraftalat), PE (polyethylene), PVC (polyvinyl chloride), PP (polypropylene), PS (polystyrene), respectively. If these species will be defined shortly;

Polietilentetraftalat (PET): Generally, water, soft drinks and fat used in the packaging of bottles. Due to the lightweight and durable usage is growing fast.

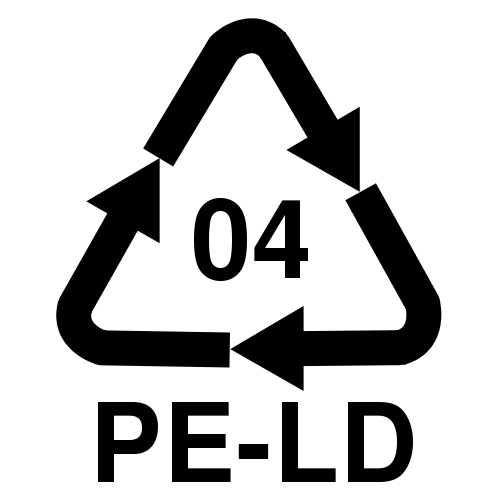

Polyethylene (PE) is a type of plastic used in most homes. Toys, detergent and shampoo bottles, packaging films, has many uses, such as garbage bags.

Polyvinyl Chloride (PVC): Water and liquid detergents, certain chemicals, health care and cosmetic products used in packaging.

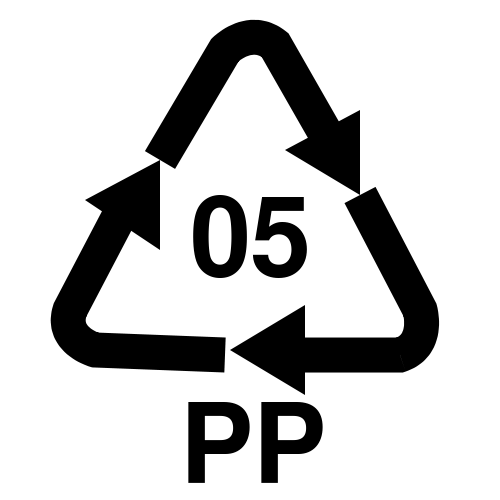

Polypropylene (PP): The detergent boxes lids, margarine containers, packaging materials, such as used. In addition, the automotive sector due to be durable and recyclability, plastic garden furniture, plastic kitchen ware are an important application area.

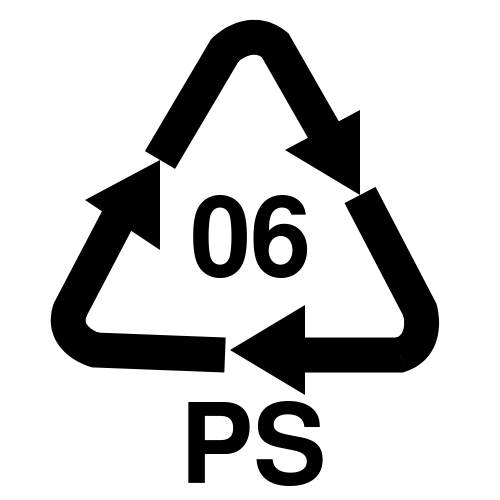

Polystyrene (PS): in the houses of the less common packaging type of packaging waste arising. Yogurt and margarine lids, disposable cups, plates are used extensively.

Polietilentetraftalat (PET)

Polietilentetraftalat (PET) Polyethylene (high density)

Polyethylene (high density) Polyvinyl chloride (PVC)

Polyvinyl chloride (PVC) Polyethylene (low density)

Polyethylene (low density) Polypropylene (PP)

Polypropylene (PP) Polystyrene (PS)

Polystyrene (PS)